Investigating the causes and remedies

CRAWLING

Definition: Wherever the tensile or surface tension between the glaze particles is greater than the tension caused by the adhesion of the glaze and the body, moisture tension or plastic tension between the particles, during the shrinking of the piece and when the glaze is still molten and has sufficient fluidity, a creep layer is being created from the glaze, which collects itself in the first stages of cooling and withdraws itself in the form of separate islands in the most common case. The side edges of the back-glazed coating that surrounds the unglazed surfaces are often thick and uniformly rounded. The severity of this condition varies from small isolated surfaces to a wide distribution, or even a rosary-like state in which the glaze is in the form of rosary beads and almost similar to water droplets on a greasy surface. The formation of wide and circular holes is another possible form of its occurrence. The complication is more severe in non-lead glazes than lead glazes.

The resulting stress between the glaze and the body causes the creation of small cracks in the glaze, which are called creep lines or Crawling. If the surface tension and viscosity of the glaze melt is high, the glaze retracts along the creep lines. The glazed layer collects in the first stages of cooling and, in the most common case, it becomes separate islands or wide and round holes. .

If the glaze melt remains in a plastic state for a long time before hardening and passing through its Solidious Point, it is not able to accompany the shrinkage of the body (or vice versa for the body). As long as the glaze loses its plasticity during cooling, the body resists shrinking due to the bands formed on the contact surface of the glaze, and in this case we face two simultaneous complications: crawling. and spalling. With the difference that the spalling problem is revealed only after cooking and during the cooling stage.

Causes:

1_ Shrinkage mismatch

1-1) Type and quantity of consumable plastic components

Single firing cycles:

In the case that the thickness of the glaze is less than the body, the glaze will be subjected to tension caused by the adhesion of the glaze and the body and moisture tension.

Double firing cycles:

If the glaze shrinkage is more than the body, the glaze will be under plastic tension between its particles.

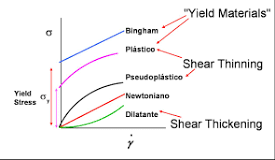

2-1) Surface tension of molten phase of stoneware bodies

The higher the surface tension of the molten phase of the stoneware bodies, the more they will tend to unconventional shrinkages.

1-3 Particle size distribution and fine grain fraction of consumable plastic components

High percentage of consumption of plastic clays with particle size distribution in the range of colloidal clay particles (with a size below 1 micron)

4-1) Type and quantity of consumable Fixative and Binder

Additives such as cellofas. Gum, starch, and CMC compounds, due to high raw-to-dry sweeteners, if used in high percentages, aggravate the creep problem.

1-5) Fine raw materials with the ability to retain hydrated water

Consumption of such materials such as uncalcined zinc oxide, talc, magnesium carbonate, aluminum hydrate, etc., cause crawling when they dry due to their high ability to retain hydrated water.

6-1) Aging and insufficient aeration

The cause of the complication is the interaction between the shrinking of the piece and the evaporation of moisture, which leads to surface cracking of the glaze and crawling. The aeration and oxidation of the plant soil reduces the severity of the complication.

7-1) Milling time

The distribution of finer graining greatly aggravates the creep for the reasons that will be discussed later.

2_ Overgrinding

(2-1 Frit hydration

The high wear causes hydration of a part of the frit and the release of water from these hydrated salts during baking causes the surface of the glaze to crack and eventually crawling.

2-2) Breaking bonds

The release of the negative charge of the salts resulting from the breaking of the bonds and its application on the clay plates changes the suspension properties of the slurry and the plasticity of the settled layer of the glaze.

2-3) Formation of more colloidal substances

High milling increases the fraction of fine material with colloidal size.

2-4) Increasing chemical activity

The reaction between materials takes place through the surface and this available surface is a function of grain size distribution. Finer grain size distribution increases the chemical activity of the particles by increasing the specific surface area. This high chemical activity due to the interactions of the buffer layer increases Surface tension and the risk of crawling increase.

2-5) Pulvirization of particles

This phenomenon leads to the production of dusty glazes with less adhesion.

2-6) The compression of the glazed coating

The finely milled glazes contain plastic clays due to the compression of the settled layer, the glaze prevents the easy exit of moisture, and the resulting pressure causes the glaze to recoil and crawl.

2-7) Cement properties of finely ground particles

The properties of the cement type of finely milled components increase the surface tension and as a result the risk of crawling.

3- Scaling and deposition of soluble salts

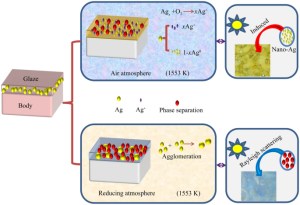

1-3) The effect of pyrolysis and decomposition of soluble salts

All three stages of pyrolysis of dissolved salts are accompanied by the release of the corresponding amount of water vapor and gas, which causes the glaze to recoil.

2-3) The effect of the drying process on the desalination process

drying scum weakens the bonding bonds of the glaze and the body in the buffer layer.

3-3) The presence of gaseous products from combustion

The penetration of these gas products into the open pores of the glaze and the body during the pre-heater stage and their reaction with the existing carbonates both causes scaling and releases a large amount of carbon dioxide gas, which destroys both the enamel and the body layers. The buffer is weakened.

4-3) Long aging of glaze slurry

Long aging of the glaze slurry causes unusual properties (in terms of viscosity and plasticity of the slurry

4_ Other causes

1-3) Boiling water, Bloating and Blistering

Improper drying causes bloating caused by boiling water and creating blisters, and eventually the glaze is rejected.

2-4) Formation of steam caused by very fast heating

The formation of steam caused by the heating of the body, which is still wet due to the glazing, weakens the bonds and the tensile stress caused by the adhesion of the glaze and the body. The first 600 degrees of single firing and the first 100 degrees of double firing should be passed for this purpose.

3-4) Vitrious body

Excessive vitrification of double-baked bodies reduces the ability of adhesion and adhesion of the glaze and the body.

4-4) The role of underglaze colors

The green and pink underglaze colors of chrome, cobalt blue and manganese brown act as a greasy surface and cause the surface glaze to retract.

4-5) The presence of dough clots

The presence of such clots in the granule under the press due to their higher humidity gives them a different contraction behavior, which leads to the creation of creep lines around the shrunken clot.

4-6) The distance between the softening point and maturity of the glaze

If the glaze starts to turn candy-like, the bubbles will split the glaze and push it back.

4-7) Dilatometric matching and buffer band

The presence of a developed middle layer free from tensile stresses is necessary to prevent creep.

4-8) high thickness and layered use of glaze layers

Deficiency in shrinkage compatibility, especially when multiple layers of glaze are layered, aggravates the creep.

4-9) Use of calamine, zinc, talc, magnesium carbonate, etc.

High raw to dry shrinkage of these materials causes creep and crawling.