Biological degradation of organic glaze additives

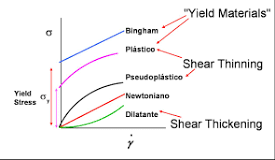

Rarely, the slurry prepared from frit and the composite components of the milling can be directly used in the glazing process. The rheological properties of the glaze slip change with time due to the distribution of the particle sizes and also their fluid properties. In order to glaze work with a constant thickness and achieve uniformity in the settled layer of the glaze, using some additives that modify the rheological properties, which are able to control the viscosity of the slip, the tendency to clot, overcome the sedimentation process, improve the wetting properties, control The drying time, as well as improving the raw strength of the glaze, is necessary.

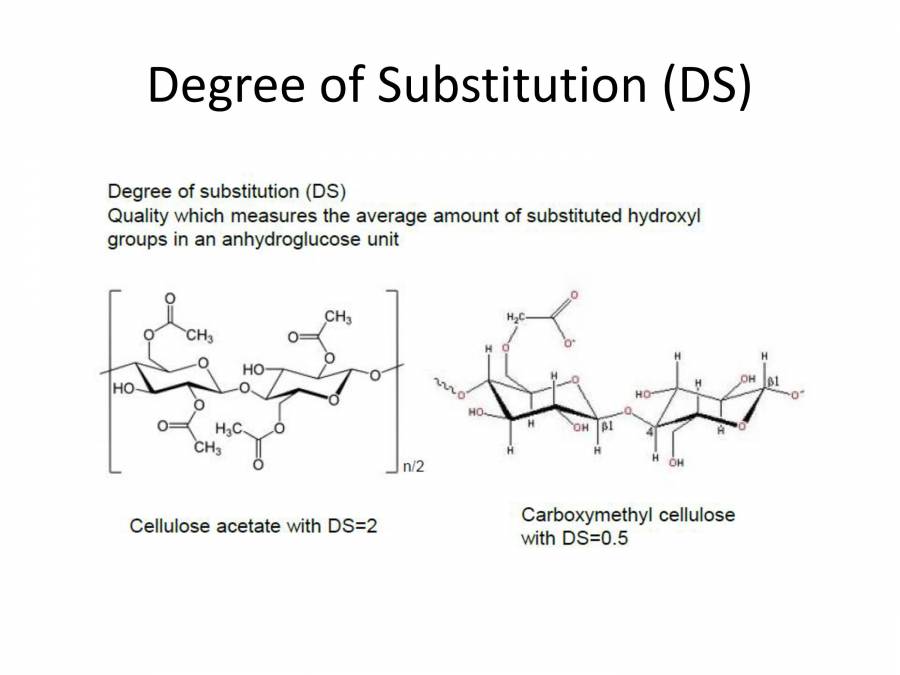

Cellulose ethers are included in the family of such additives. Cellulose is partially amorphous and partially crystalline solid and insoluble in water. However, with the help of etherification reaction, its derivatives are obtained which are soluble in water. In such derivatives, due to the substitution of hydroxyl branches on the cellulose chain by carboxymethyl groups, the arrangement and properties of the basic cellulose molecules are changed.

Polyanionic softening and anti-caking agents, which are considered soluble complex salts of sodium and phosphoric acid, are also in the family of such additives. Sodium tripolyphosphate and sodium metaphosphate can be used as deflocculating agents in glaze slip and obtain a liquid suspension. Determining the effective consumption of these anti-caking agents depends on the amount of acrylamides and acrylic acid salts available. Such additives are polyelectrolytes with low molecular weight that have the ability to absorb on the surface of the particles that make up the glaze slurry.

During the aging of slips, the viscosity of suspensions in which organic components and polymers with high molecular weight are used as adhesives depends on the length of the polymer chain and their molecular weight.

If the polymer chain connection is broken, the viscosity of the slip will decrease with time. Such failures may be the result of mechanical damage during milling, heat, hydrolysis, oxidation and enzymatic reactions. Many of the organic adhesives added to the glaze slurry are chemically decomposed in sufficient heat and as a result of the attack of bacteria and fungi. Bacteria may consume organic components and compounds as a source of carbon and energy. In such conditions, it is necessary to use bacteriostats and bacteriocides in order to control the growth of bacteria.

Microbial growth may produce an enzyme that breaks down cellulose derivatives and releases gas bubbles over time. The creation of a pungent smell and loss of fluid properties of the slurry are also other effects of this decomposition of cellulose derivatives.

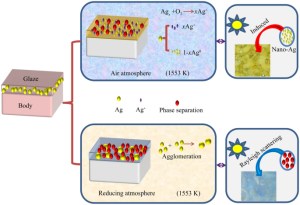

During glaze firing, adhesives and organic suspending additives of glaze, like other organic mediators used in most decoration processes, begin to decompose at temperatures around 110 degrees Celsius, and such decomposition is accompanied by the release of water vapor and carbonate vapors. , and gases containing carbon dioxide and various hydrocarbons will be accompanied.

Carboxymethyl cellulose is also among the compounds that are subjected to biological decomposition and are damaged due to the contact and attack of enzymes produced by certain bacteria. It is possible to provide the necessary stability against the contact and attack of bacteria by using biocides.

Another type of contact and biological attack is done by polyvalent cations. The polyelectrolyte part of carboxymethyl cellulose, which provides the possibility of binding with cations, is no longer able to perform its rheological functions and retain water molecules, and is considered useless and lost in any way. Many classic lubricants such as sodium tripolyphosphate, hexametaphosphate and polyacrylates also suffer from similar complications in these conditions.

The majority of ferrites, pigments and raw materials used in the formulation of glaze slurry, as a result of partial dissolution, it causes gradual contamination and “poisoning” of CMC and thus changes the characteristics of the glaze. The above complication is interpreted as deterioration and corruption of CMC, but in fact it is a defect related to the glaze and naturally, in such conditions, the use of biocides is useless.

Formation of foam and boils are among other defects of suspensions that have been used with organic adhesives to control their rheological properties. The presence of such unwanted defects in the glaze is not very desirable because there is always a direct correlation between the presence of bubbles and the quality loss of the glaze. The amount of bubbles formed and their stability depends on the viscosity of the slip, the pH level, and the type of CMC used. Some factors that cause instability in the layers lead to the formation of bubbles and foam. In case of using defoaming and anti-caking agents, there should be a degree of non-dissolution and incompatibility between them so that they can affect the surface of the layers.

Carboxymethyl cellulose is obtained by adding carbon methyl groups to cellulose chains. The average number of these groups in each monomeric unit is called “degree of substitution” or “DS” for short. The stability against the contact and attack of bacteria is improved by increasing “DS”.

With the help of preservatives, it is possible to prevent the decomposition of organic glaze adhesives during the storage period and also during the attack of fungi and bacteria.

Most of the manufacturers of glazing additives can provide the necessary recommendations for choosing the right preservatives.

By: Omid Holakoue