The application of the chemistry of noble metal nanoparticles in the preparation of digital printing inks

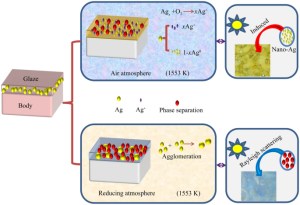

In recent years, the field of nanotechnology and nanoparticle science has expanded at such a speed that it has made its various practical applications in the field of ceramics inevitable. One of the main goals of nanotechnology research is to understand the behavior of materials when their size approaches atomic dimensions. Nowadays, this attention is especially focused on metallic nanoparticles, including noble metal nanoparticles. The chemistry of noble metal nanoparticles is a field of chemistry that has rapidly growing applications in catalysts, biosensors, electronics, and optics. Since this structure is intermediate between molecules and bulk materials, it is able to create a bridge between molecular chemistry and surface science. The most important feature of these noble metal nanoparticles is their optical properties. The properties that have so far and in the future will cause the innovations that are expected from it. The most significant optical property of this chemical structure is its strong absorption band in the visible spectrum, which is called the Plasmon band. Colloidal solutions of gold, silver and copper are the most known types of this chemical structure. The tunable optical properties of this family of metals are caused by the continuous and cumulative oscillation of the conduction electrons inside the nanoparticles, which results in the plasmon band resonance. This band is a strong absorption band in the visible spectrum. The wide optical field of these metals creates strong absorption and differentiation of light rays. As mentioned, the optical capabilities of noble metal nanoparticles come from the resonant oscillation of their free electrons in the presence of light, which is called surface plasmon band resonance. Also, by changing the shape and size of noble metal nanoparticles, we will be able to adjust the quality and resonance properties of their plasmon band. In addition to oxides, another group of suitable materials for the preparation of digital printing inks are metals. Although the use of noble metal nanoparticles in the preparation of colored glass and glass covers of chandeliers has a long history, today they are widely used in creating a palette of colors from yellow to red. It is used in transparent glasses and glazes. The color obtained from these materials is obtained by the Surface Plasmon Resonance mechanism of a number of nanoparticles. A mechanism that is used today by the tile and ceramic industries and through digital printing techniques. Placed. Nanoparticles of noble metals are synthesized through various chemical methods, a mechanism that in many cases focuses on May’s methods. Recently, the technical knowledge of syntheses related to the production of nanoparticles of noble metals in aqueous media have also been presented. A technique in which the use of harmful agents is minimized. In this method, salt precursors obtained from reduced glucose are used, and metallic nanosuspensions with a high percentage of solid components are obtained, which have excellent stability. In addition, the high adaptability of the production process of inorganic core-shell structures or alloy nanostructures such as AuAg and AuCu with the ability to adjust the color shade has made it possible. A number of compounds obtained from noble metals in the form of colloidal suspensions have been noticed in the fields of ceramics and digital printing inks. This attention is due to optical properties, chemical stability, and properties that are affected by particle size. In these colloidal suspensions, particles can be prevented from coagulation with the help of additives such as thiols or amine compounds. Various synthetic methods have been presented in order to prepare nanoparticles with the ability to suspend in the suspension phase. These fuzzy methods are based on organic solvents. Synthesis of core-shell hybrids of noble metals Nanoparticles of noble metals – of various sizes – by combining with polymers containing conjugated structure, create core-shell hybrids that have specific physical characters and various applications. Synthesis of core-shell structures based on noble metal nanoparticles show that the metallic core of this structure is surrounded by a shell of copolymers. This hybrid structure includes a core of noble metal nanoparticles covered by copolymers of methanol, tetrahydrofuran, polyacetylenes, etc. The above polymer shell contains chemical agents such as diol, phenyl, ammonium or, in medical applications, thiol groups. The properties of hydrophilicity or hydrophobicity, as well as the solubility of the core-shell structure, are the criteria for choosing each of these chemical agents. The chemical structure of the polymer shell, particle size, grain distribution and optical properties of the mentioned hybrids determine the variety of applications of these conjugated structures. Usually, the average size of the metal core is about 10 to 30 nm and its polymer shell is about 2 nm thick. Preparation of core-shell hybrids with the help of reducing metal salts In the field of ceramic applications, silver nanoparticles have received special attention. There are various methods for the controlled synthesis of silver nanoparticles. Chemical regeneration is one of these methods. With the help of this method, silver nanoparticles are obtained in the colloidal phase dispersed in water or organic solvents. The reduction of silver ions in aqueous solutions yields colloidal silver with a size of several nanometers. This synthesis usually takes place in the presence of stabilizers in order to prevent the coagulation of colloids. Recently, third type amines have also been used to form silver nanoparticles in organic media. Amine-derived complexes are also used in the synthesis of silver nanoparticles. The preparation of core-shell hybrids is done by reducing soluble salts in the presence of polymeric solutions. The size and shape of nanoparticles synthesized by the ion reduction method in solution, It usually depends on a number of parameters. These parameters include the reducing agent, and how to charge the metal precursors participating in the synthesis. The regenerative factor determines the speed of the germination and growth process. Slow regeneration of coarse particles and fast regeneration of finer particles are obtained.